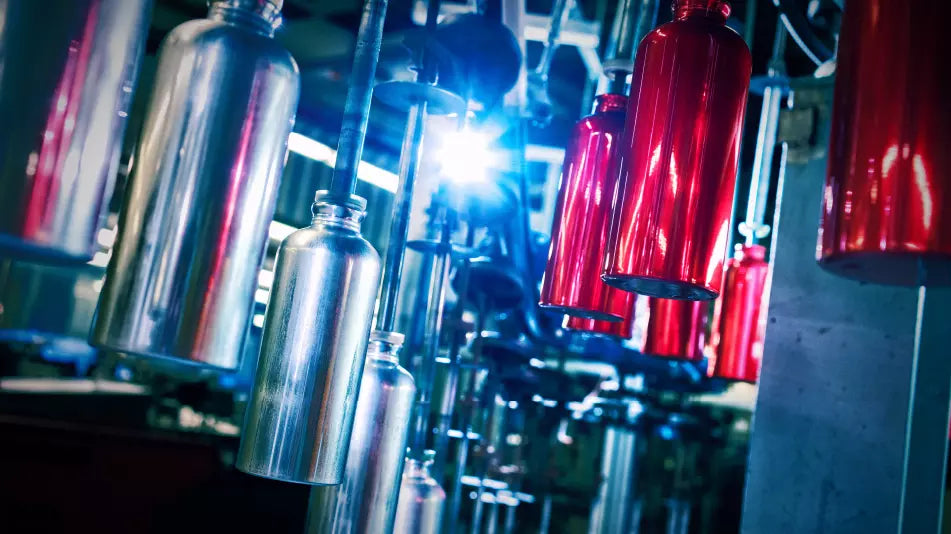

It all starts with a disc of aluminum. This is formed into a cylinder by a 600-ton piston stroke along the piston. The cylinder is formed into a bottle using up to 26 differently designed mold blocks, each of which moves the metal further towards its final shape. Once the bottle has achieved its iconic shape, the inside of the bottle is coated with our interior varnish to avoid direct contact between the liquids and the aluminum.

Founded in 1908, SIGG produces bottles in Switzerland with the overarching goal of keeping environmental impact as low as possible. Thanks to innovative solutions, the "ecological footprint" has been continually reduced. Today, SIGG uses energy in bottle production that comes from more than 55 percent of renewable sources. The small amount of waste from production is 99 percent recycled and the water used to clean the bottles is also collected and recycled in a closed system. Thanks to the durability of the high-quality and reusable aluminum bottles, SIGG aluminum drinking bottles have a significantly better CO² balance than a disposable PET bottle.